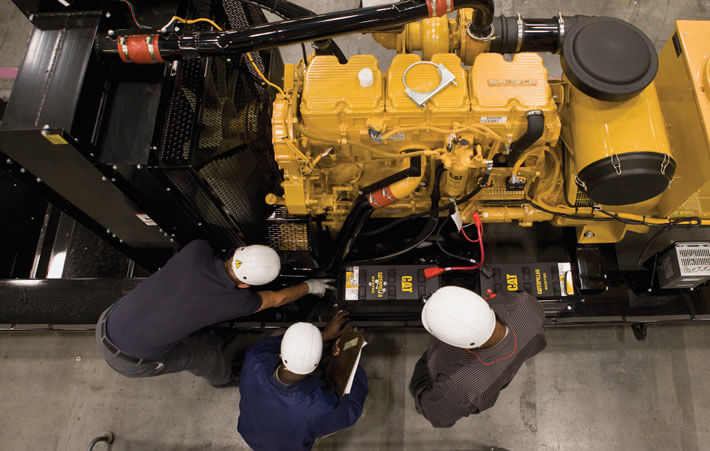

When purchasing diesel generator sets for the first time, many customers only pay attention to the power of the engine set and ignore many more important details. The key to whether a diesel generator set can maintain its working efficiency steadily lies in various optional combinations. In terms of adaptability, Title Power found through years of assembly and a large number of after-sales summaries that the better the adaptability of all components of the unit, the better the stability of the diesel generator set and the lower the failure rate.

For engines without brand and power, due to the differences in production process, internal structure and quality of selected materials, the corresponding requirements for other parts are also different. For example, some parts suitable for 100KW Dongfeng Cummins are used when 100KW Yuchai is used. There is a high probability of failure.

Like the cylinder, the core component of the engine block, during operation, the surface of the cylinder must alternate between high temperature, high pressure gas and low temperature fresh air. Under the dual influence of gas pressure and temperature changes, the air filter is selected. Or the air boost system will determine the wear problem of the cylinder surface, which will seriously affect the service life of the diesel generator set; therefore, engines of different brands and powers will be added to the cylinder production such as high phosphorus cast iron, boron-containing cast iron, ductile iron or Different wear-resistant alloy materials such as austenitic cast iron can improve the wear resistance of the cylinder.

In addition, commonly used cylinder liners are divided into two types: dry and wet:

The dry cylinder liner is a thin-walled cylinder with a wall thickness of 1~3mm. Its characteristic is that the outer surface of the cylinder liner does not directly contact the cooling water. The advantage of using a dry cylinder liner is that the rigidity of the body is better, and there is no cooling water sealing problem; the disadvantage is that the heat dissipation condition of the cylinder liner is not as good as that of the wet cylinder liner, the processing surface is increased, the cost is high, and the disassembly is difficult.

The wet cylinder liner is a cylinder with a wall thickness of 5-9mm, the outer wall of which directly contacts the cooling water. The advantages are convenient assembly and disassembly, reliable cooling and easy processing. Most diesel engines use wet cylinder liners. The disadvantage is that the rigidity of the body is poor and the possibility of water leakage is relatively high.

Therefore, when the unit selects the air filter, booster system and diesel model, it must be selected according to the corresponding cylinder, so as to control the purchase cost and ensure the stability of the diesel generator set. Realize worry, effort and money saving.

In the electrical age, no matter what dangerous place, as long as there is human civilization, electricity is inseparable. Title Power is powered by the brand and cooperates with the self-developed silent protection assembly process, so that the power generation unit can always guarantee power supply whether it is in the alpine or subtropical zone.