Civil diesel generator sets have the advantages of high speed, supercharging, low fuel consumption, high reliability, large capacity, and small space. They are widely used in leisure and entertainment places such as fast hotels and Internet cafes. However, because most civil diesel generator sets All have short continuous working time and poor environmental adaptability. Therefore, in the absence of corresponding protective measures or sudden bad weather, failures such as poor start-up are prone to occur, and common start-up failures are mainly due to low start-up battery voltage and actual capacity Insufficient <display voltage is a virtual voltage>; starting battery cable and motor wiring error; starting motor electromagnetic switch failure, etc.

When encountering a poor startup failure, you can deal with it according to the following methods:

1. Use a multimeter to measure whether the voltage of the single battery and the DC output of the charger are normal, check the liquid level of the lead-acid battery, and add distilled water in due course;

2. Disassemble the motor, check and adjust the contacts in the electromagnetic switch, if the contacts are burned out, replace the electromagnetic switch;

3. Check if the battery negative cable is grounded (chassis), the wiring is wrong, just reconnect the cable;

4. Use a multimeter to measure the resistance of the starting contactor coil of Cummins, Callerbit and Wilson diesel engines (the resistance is generally in the tens of ohms), if it is abnormal, replace the contactor;

5. Adjust the outer middle screw of the starter motor of CIMC 495 diesel engine to a strong position.

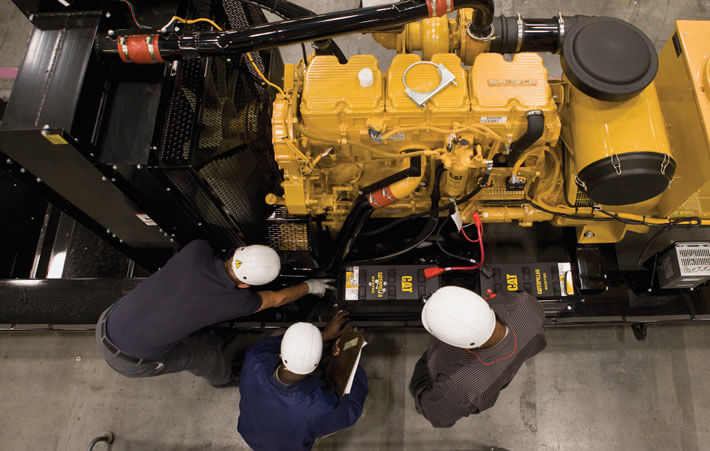

Title Power starts with anti-vibration details and EU screw hole design standards, no matter what kind of power generator sets are working, they can be as stable as Mount Taishan; maintenance plans are made according to the environment and power used by customers to improve the safety performance of open-frame generator sets and effectively extend the generator sets Service life.